Co-Founder & CEO, Manufacturing, Product Management, Quality Assurance

What is Plasmonic Sensing :

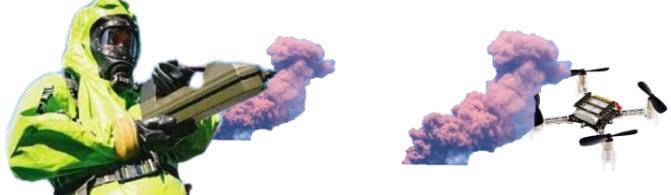

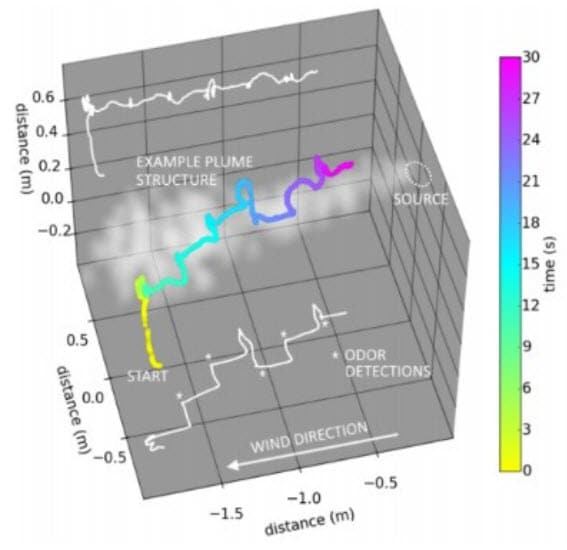

Plasmonic sensing is a groundbreaking solution initially scoped for military applications to protect solders and first responders from entering areas of chemical warfare by means of UAV CBRN detection. Now we are revolutionizing plasmonic sensing in manufacturing and logistical fields of Food and Beverage, Oil & Gas, Chemical, Cleantech, Medical, and Pharmaceutical. The solution is a sophisticated sensor that mimics the olfactory sensory by using a vision data collection technology to determine what chemical agents are present immediately. This technology is used to complement PCR and culture testing to help private and public sector customers bring awareness in a real-time manner to their quality and safety risks within their respective environments.

At ValorTrac, our unwavering dedication is to empower those who tirelessly serve, protect, and uplift our communities–from the military and law enforcement to emergency responders and essential industries. As a veteran-led, dual-use technology firm, we innovate with integrity, passion, and excellence, prioritizing the needs of those in defense, public safety, healthcare, agriculture, and manufacturing. Our core purpose is to stand beside and support the very individuals and sectors that form the backbone of our society.

Empowering decisions with immediate results. Our plasmonic sensor technology reduces risks for public and private industry customers by being capable to detect multiple foreign biochemical, virus, and bacterial agents simultaneously in real-time. Our cutting edge technology also allows our sensor to be reusable between test samples, compact with low power consumption, and maintain a high efficiency and sensitivity. Can you imagine being able to detect a chemical agent in your food manufacturing facility, and then detecting a foodborne agent only seconds from your first detection. Our main goal is to provide immediate awareness to the detection of any agent in order to make quicker decisions to minimize exposure or losses.

The design of our sensor uses the basic properties of plasmonic nanoparticles and photonic crystals. When a noble metal nanoparticle is irradiated with light, its surface electrons begin to oscillate coherently, generating a strong localized electromagnetic field. Also known as a surface plasmon resonance, this field is extremely sensitive to changes in its vicinity. Also known are the color changing characteristics of spatially varying photonic crystals and their sensitivity to changes in the index of refraction of one of its constituent materials. Our invention combines these two effects to generate a novel, multivariable hybrid sensor – our device consists of biologically inspired spatially-varying photonic crystal wells filled with plasmonic nanoparticles.

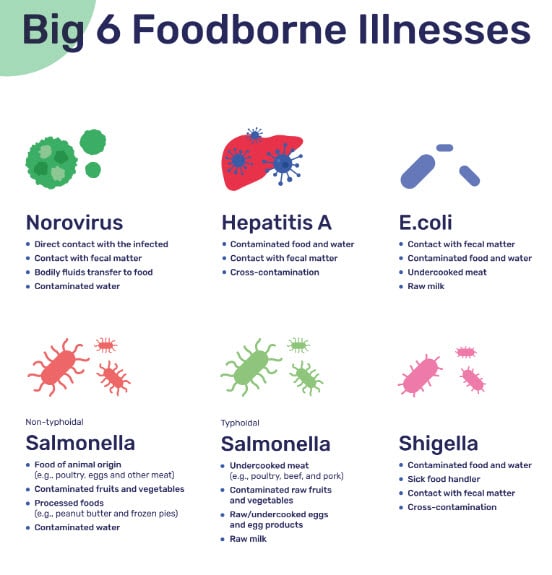

Food and Beverage

Provide foodborne agent detection along the whole food and beverage supply chain from raw materials, transportation, manufacturing, warehousing, and retail locations.

Foodborne Agents

Pharmaceutical

In pharmaceutical manufacturing, the focus of our stationary and mobile sensors would be primarily ensuring an immediate result of any agents that affect the sterility and purity of pharmaceuticals, especially those intended for parenteral administration (injections, intravenous infusions, etc.).

Antimicrobial Agents

Co-Founder & CEO, Manufacturing, Product Management, Quality Assurance

President, Founder & Owner, Defense & Gov’t Liaison & Veteran

Co-Founder & CEO, Manufacturing, Product Management, Quality Assurance

President, Founder & Owner, Defense & Gov’t Liaison & Veteran